Related Post: 3D Printed Tire / High Definition 3D Printing Design /3D Leather and Quilted Panels

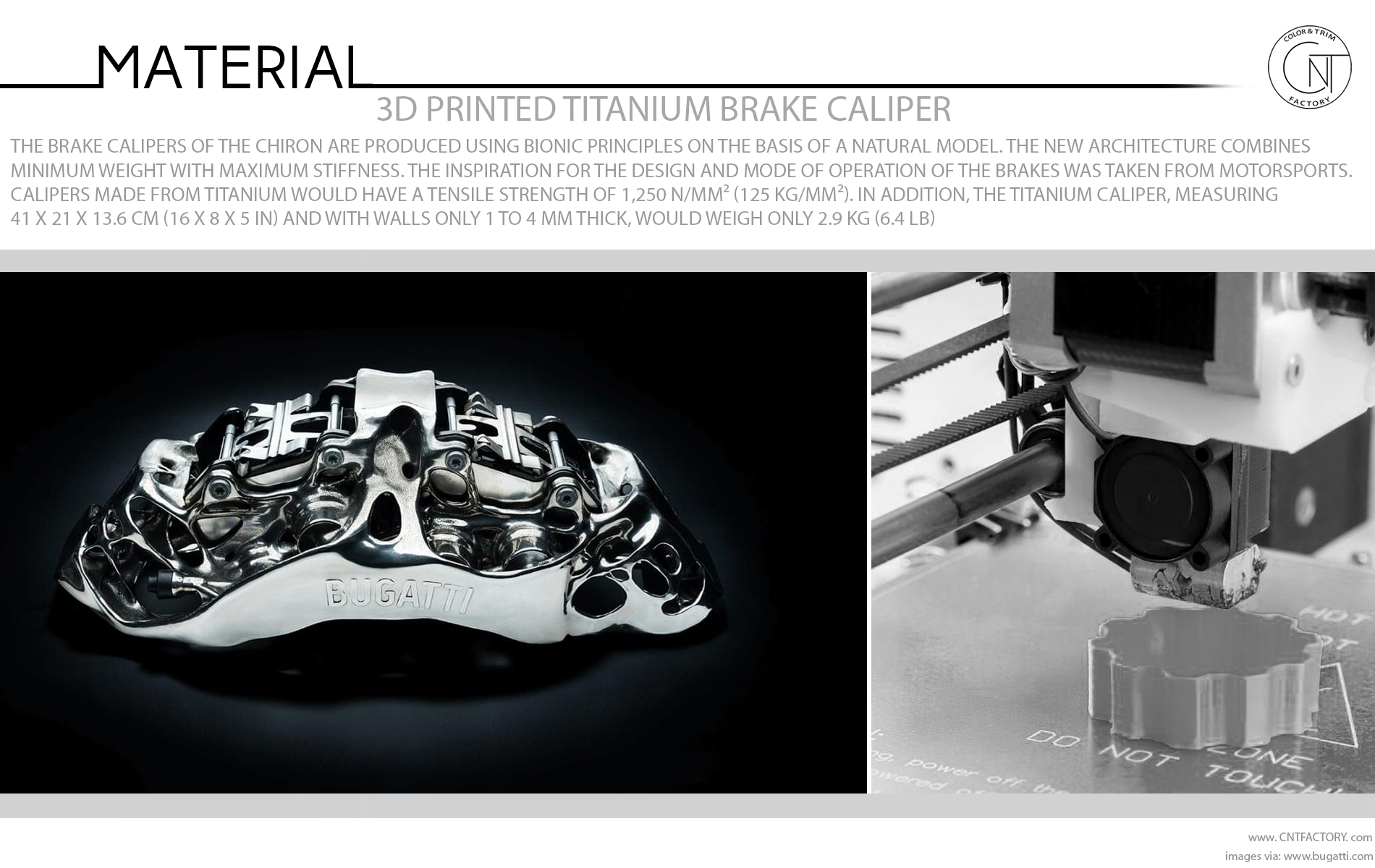

The new calipers are meant to combine minimum weight with maximum stiffness, but Bugatti felt there was room for improvement, so the company’s engineers came up with another version made entirely of an aerospace titanium alloy called Ti6AI4V, which is normally used in highly stressed undercarriages, wing components, and jet and rocket engines.

With the newly developed titanium brake caliper from the 3-D printer, Bugatti is now going one step further and breaking new ground. This particular titanium alloy, with the scientific designation of Ti6AI4V, is mainly used in the aerospace industry, for example for highly stressed undercarriage and wing components or in aircraft and rocket engines. The material offers considerably higher performance than aluminum. For example, even as a 3-D printed component, it has a tensile strength of 1,250 N/mm2. This means that a force of slightly more than 125 kg be applied to a square millimeter of this titanium alloy without the material rupturing. The new titanium brake caliper, which is 41 cm long, 21 cm wide and 13.6 cm high, weighs only 2.9 kg. In comparison with the aluminum component currently used, which weighs 4.9 kg, Bugatti could therefore reduce the weight of the brake caliper by about 40% at the same time as ensuring even higher strength by using the new part.

Bugatti says that printing the caliper took only 45 hours, which is a remarkably short time for making a complex prototype. During the process, the printer laid down 2,213 layers of fine titanium alloy powder one at a time. After each layer was set down, the lasers, guided by the design files, fused the alloy into a cross section of the caliper along with temporary support structures that cooled and solidified instantly, before the machine repeated the process.