Sorry, this content is for members only.

Join To View ThisRelated Post: Regenerated Nylon ECONYL® / Recycled Plastic by Ecobirdy / Sulapac® Biodegradable Material

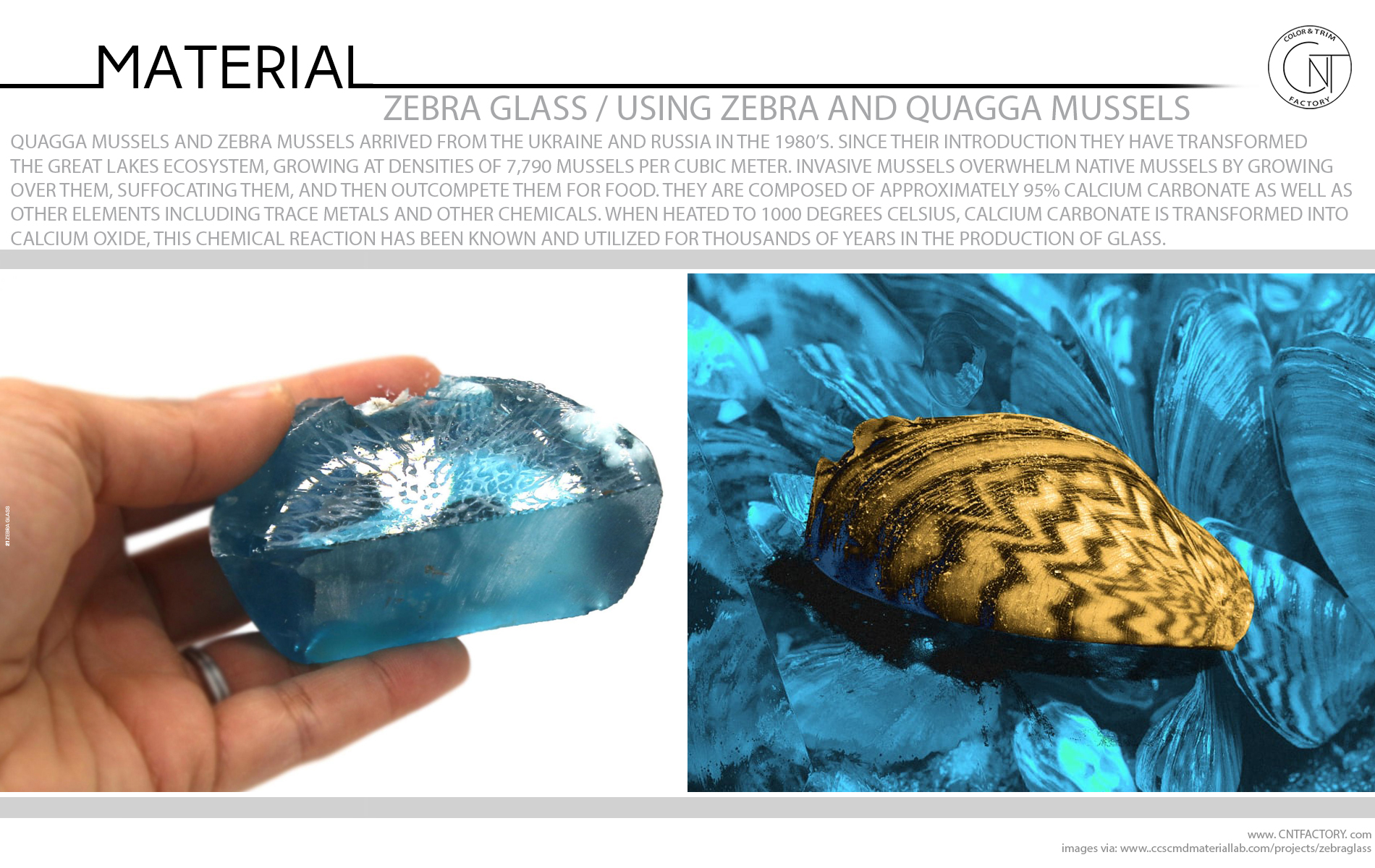

Quagga mussels and Zebra Mussels arrived from the Ukraine and Russia in the 1980’s. Since their introduction they have transformed the great lakes ecosystem, growing at densities of 7,790 mussels per cubic meter and proliferating at depths of 540 feet. Invasive mussels overwhelm native mussels by growing over them, suffocating them, and then outcompete them for food.

Looked at as a material resource, zebra and quagga mussel shells are composed of approximately 95% Calcium Carbonate as well as other elements including trace metals and other chemicals that they bioaccumulate.

When heated to 1000 degrees Celsius, Calcium Carbonate is transformed into calcium oxide, This chemical reaction has been known and utilized for thousands of years in the production of glass.

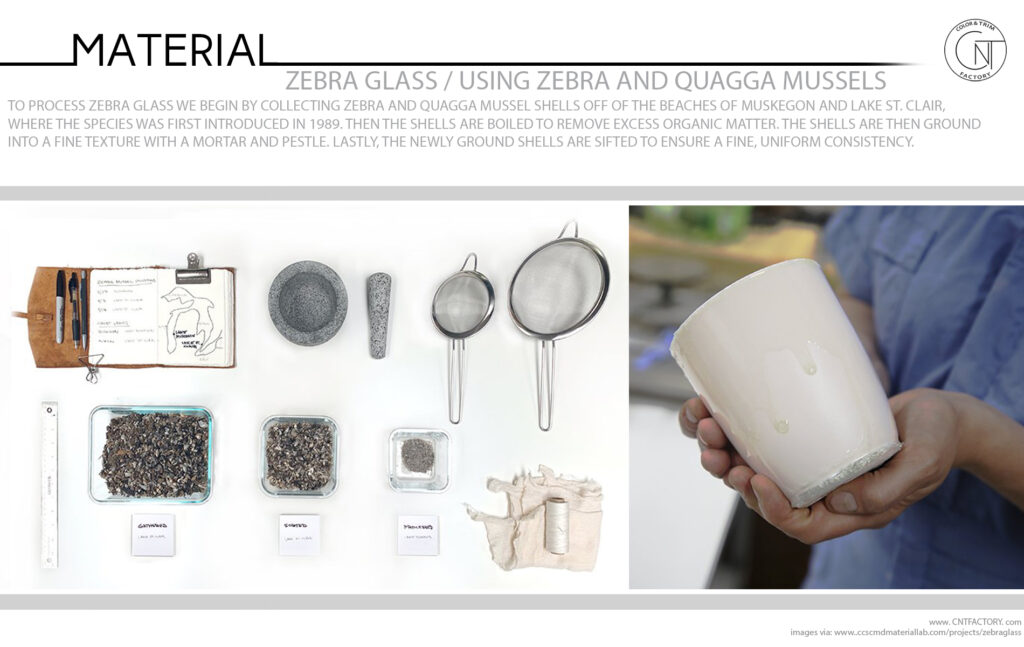

To process zebra glass begins by collecting zebra and quagga mussel shells off of the beaches of Muskegon and Lake St. Clair, where the species was first introduced in 1989. Then the shells are boiled to remove excess organic matter. The shells are then ground into a fine texture with a mortar and pestle. Lastly, the newly ground shells are sifted to ensure a fine, uniform consistency.

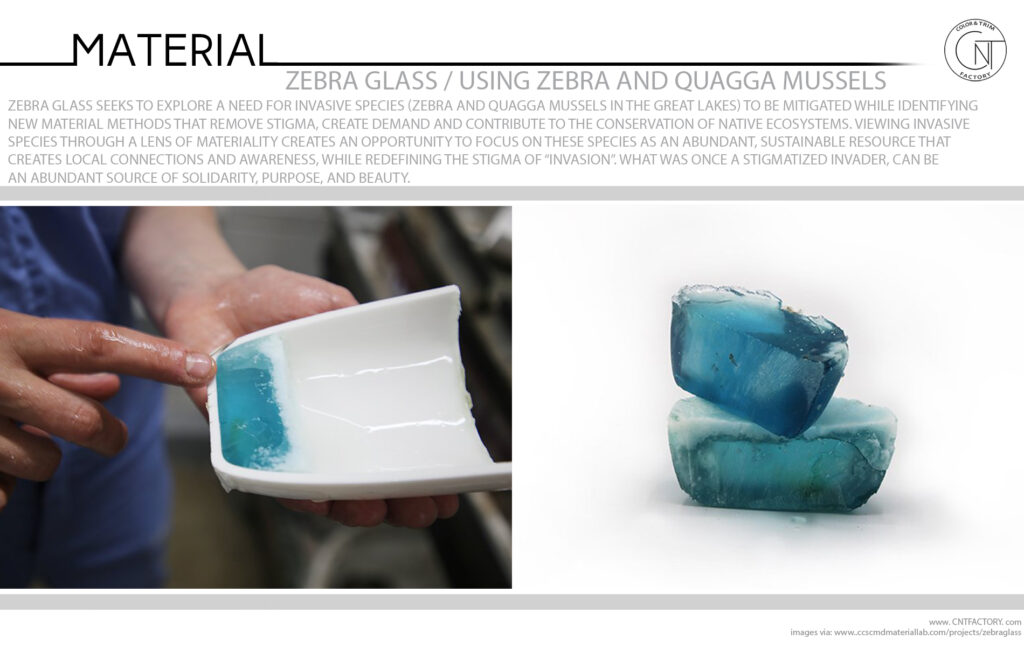

Zebra Glass seeks to explore a need for invasive species (Zebra and Quagga Mussels in the Great Lakes) to be mitigated while identifying new material methods that remove stigma, create demand and contribute to the conservation of native ecosystems. Viewing invasive species through a lens of materiality creates an opportunity to focus on these species as an abundant, sustainable resource that creates local connections and awareness, while redefining the stigma of “invasion”. What was once a stigmatized invader, can be an abundant source of solidarity, purpose, and beauty.

Instructor: matthew strong

Design team: emily marquette, mahsa banadaki, wei huang