Sorry, this content is for members only.

Join To View ThisRelated Post: 3D Printed Metal Space Fabric / High Definition 3D Printing / 3D Printed Aluminum

The Austrian design studio, EOOS, has developed a zero-emissions utility vehicle , created using 3D printing and recycled materials. The 3D printed electric tricycle was made from 70kg of waste collected from various supermarkets in the Austrian capital. The Austrian studio worked with the association The New Raw to carry out this project. The association surfs on this idea of circular economy by giving a second life to everything we can throw away.

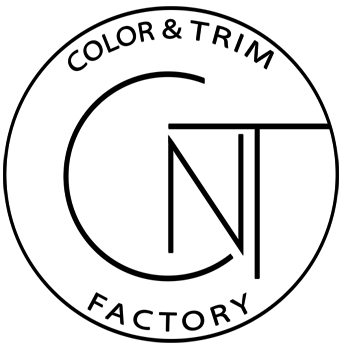

Single-use plastic packaging may help keep produce fresh, but subsequently becomes a huge environmental problem when tossed in the trash. Looking to repurpose waste from our throw-away society, a social enterprise/industrial design studio has created an electric cargo trike concept with a chassis 3D printed from supermarket plastic waste. Plastic waste is a gargantuan problem, with a recent study projecting that 1.3 billion tonnes could be dumped on land and in the oceans by 2040.

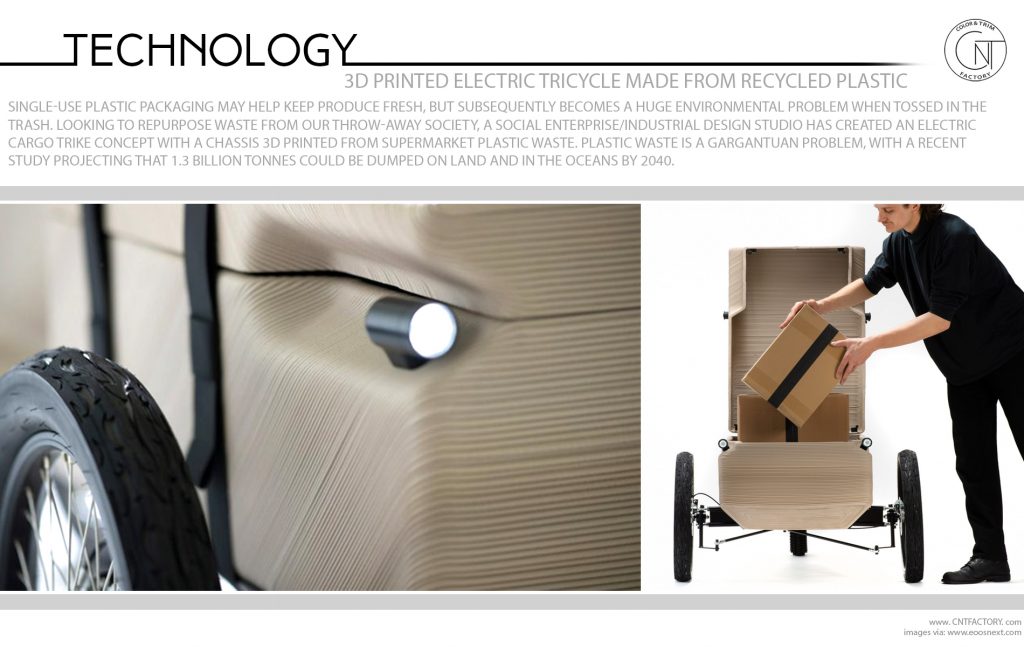

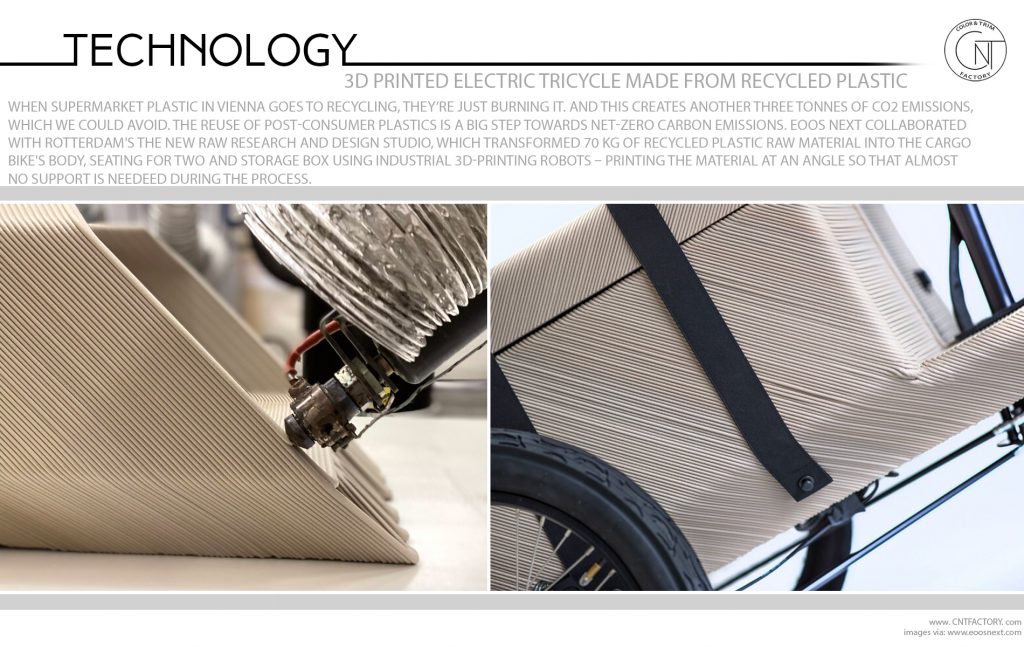

EOOS NEXT collaborated with Rotterdam’s The New Raw research and design studio, which transformed 70 kg of recycled plastic raw material into the cargo bike’s body, seating for two and storage box using industrial 3D-printing robots – printing the material at an angle so that almost no supports were need during the process. But we want a local ZUV production facility in every city around the world. And ultimately, the chassis could be shredded and re-printed to form another ZUV.

When supermarket plastic in Vienna goes to recycling, they’re just burning it. And this creates another three tonnes of CO2 emissions, which we could avoid. The reuse of post-consumer plastics is a big step towards net-zero carbon emissions. EOOS NEXT collaborated with Rotterdam’s The New Raw research and design studio, which transformed 70 kg of recycled plastic raw material into the cargo bike’s body, seating for two and storage box using industrial 3D-printing robots – printing the material at an angle so that almost no support is needeed during the process.

Created in collaboration with additive manufacturing company The New Raw, the ZUV is powered via a rear-wheel hub motor without the need for pedals or a bike chain.