Sorry, this content is for members only.

Join To View ThisRelated Post: 3D Woolen Felt / Deconstructed Felt By Patcraft

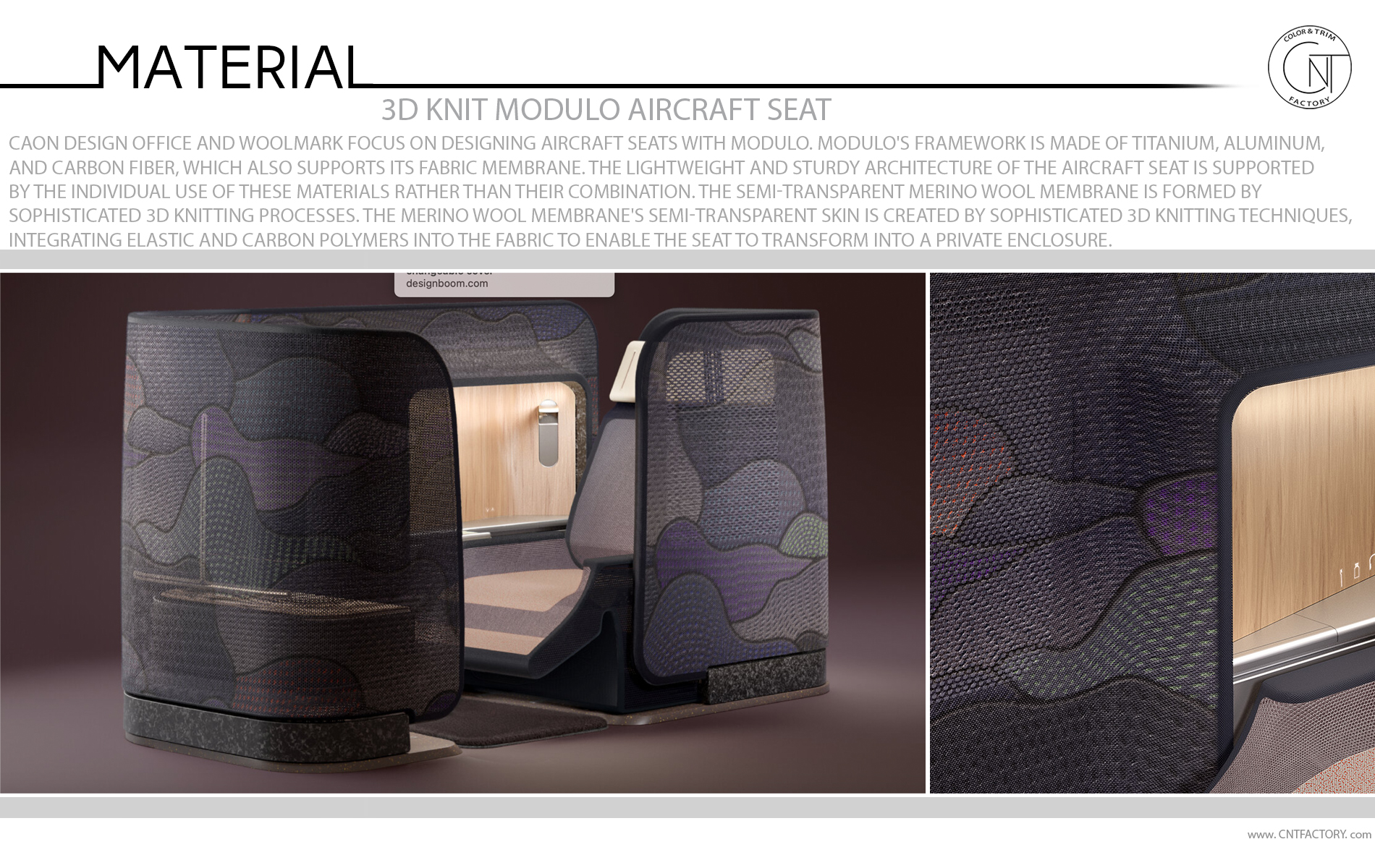

Caon Design Office and Woolmark focus on designing aircraft seats with Modulo. Modulo’s framework is made of titanium, aluminum, and carbon fiber, which also supports its fabric membrane. The lightweight and sturdy architecture of the aircraft seat is supported by the individual use of these materials rather than their combination. The semi-transparent Merino wool membrane is formed by sophisticated 3D knitting processes.

The Merino wool membrane’s semi-transparent skin is created by sophisticated 3D knitting techniques, integrating elastic and carbon polymers into the fabric to enable the seat to transform into a private enclosure.

Caon and Woolmark collaborated, highlighting the benefits of the Australian Merino Wool brand, including its strength, next-to-skin softness, innate versatility, technical advantages, and 100% natural, renewable, and biodegradable fiber. The elastic and carbon polymer-infused fabric allows the seat to transform into a private enclosure.

Modulo’s semi-transparent wool mix structure, which is fashioned to resemble a 3D-knitted shell, makes it possible for passengers to feel more comfortably enclosed without having to leave the open air of the airplane. In situations when a denser, thicker, and more sound- and vibration-absorbing area is required, the Modulo wool mix construction permits the use of wadding within specific fabric portions rather than traditional foam.