Sorry, this content is for members only.

Join To View ThisSimilar Posts: Textile in Product Design / Gradient Textiles / Soft Tactile Audio Technologies

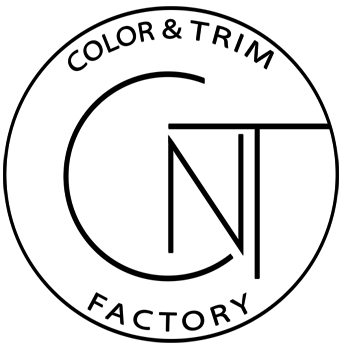

Syre is a textile impact company on a mission to decarbonize and de-waste the textile industry through textile-to-textile recycling at hyper scale, starting with polyester. At unprecedented speed and scale, Syre aims at driving the green shift of the textile industry to a future where every textile fiber sees a new day. The company’s textile-to-textile recycling solution provides circular polyester with quality on par with virgin polyester, but with a superior sustainability performance. Founded in 2023, Syre is initiated by Vargas and H&M Group. The name translates to oxygen in Swedish and is a combination of sy (Swedish for sewing) and re (Latin for over and over again).

The Syre textile-to-textile recycling solution provides circular polyester with quality on par with virgin polyester but with superior sustainability performance, reducing CO2e by up to 85% compared to the production of oil-based virgin polyester.

Polyester recycling company Syre has raised $100 million to help finance construction of a pilot plant in the US this year, pave the way to start building two commercial facilities by 2025 and complete the acquisition of the patented technology underpinning the venture.

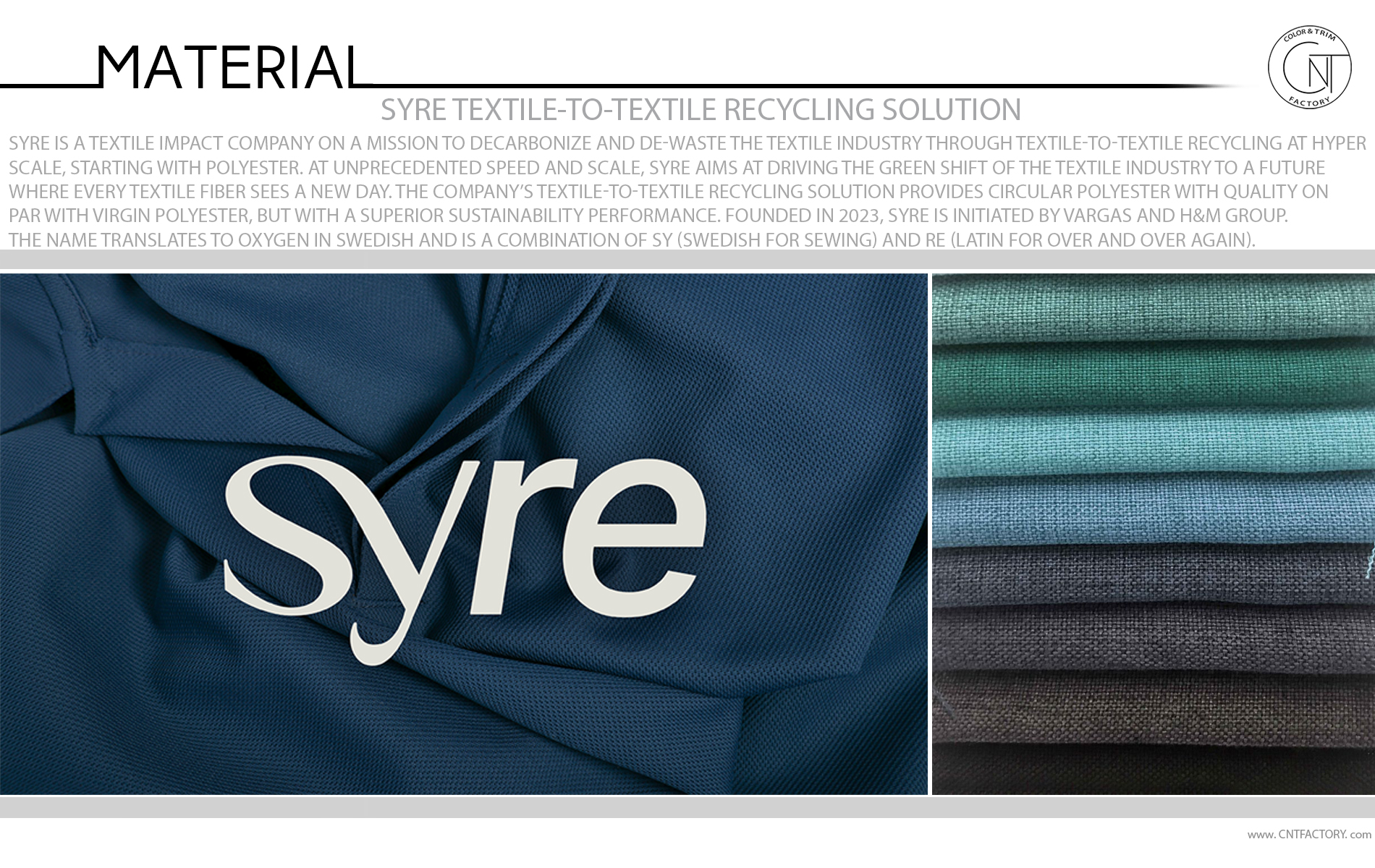

Syre was launched by H&M Group and green industry investor Vargas in March to mass produce recycled materials, starting with polyester, a huge contributor to the fashion industry’s emissions.The series A round nearly doubles the $60 million put in by the venture’s initial backers, including private equity firm TPG. Both TPG and H&M provided additional capital, alongside new investors Giant Ventures and Norrsken VS, Volvo Cars and Ikea-owner Ingka Group’s Imas Foundation.

The mix of high-profile players gives Syre clout at a challenging moment for the textile recycling space. Though incoming regulations are amping up pressure on brands to increase their sourcing of recycled materials, technologies that could turn old clothes back into new fibres have so far struggled to scale.

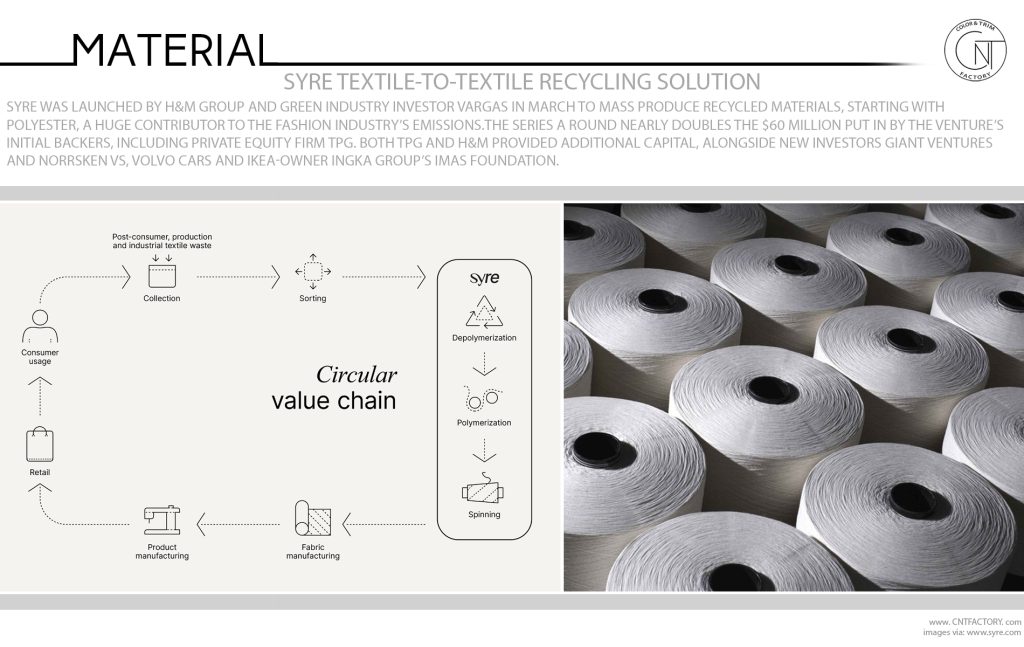

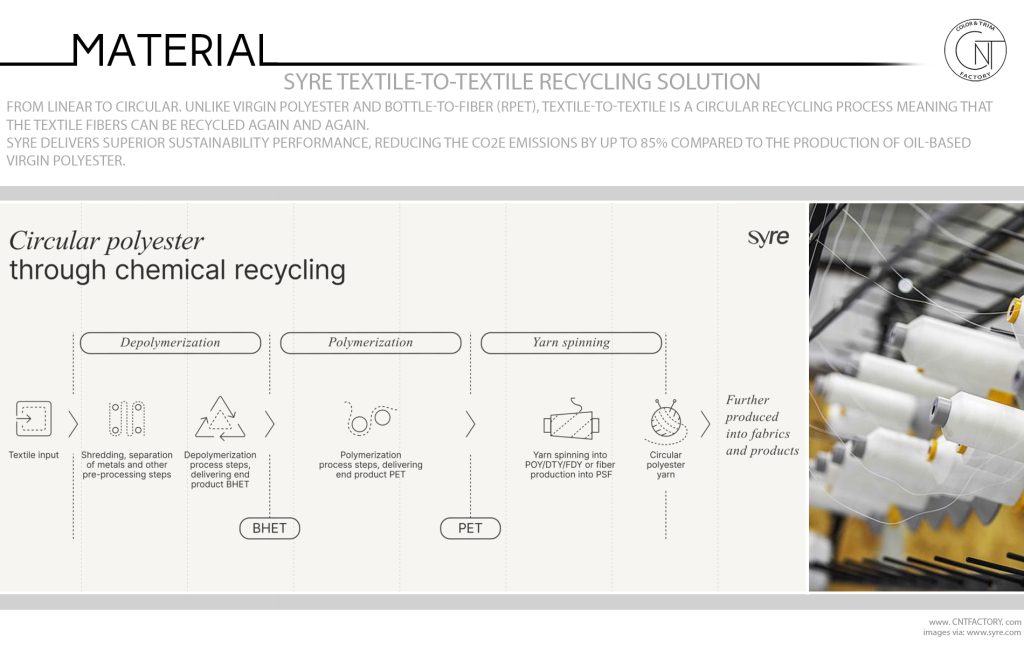

From linear to circular. Unlike virgin polyester and bottle-to-fiber (rPET), textile-to-textile is a circular recycling process meaning that the textile fibers can be recycled again and again.

Syre delivers superior sustainability performance, reducing the CO2e emissions by up to 85% compared to the production of oil-based virgin polyester.