Sorry, this content is for members only.

Join To View ThisRelated Post: MYLO Mushroom Leather / Leather Gradient / 3D Leather

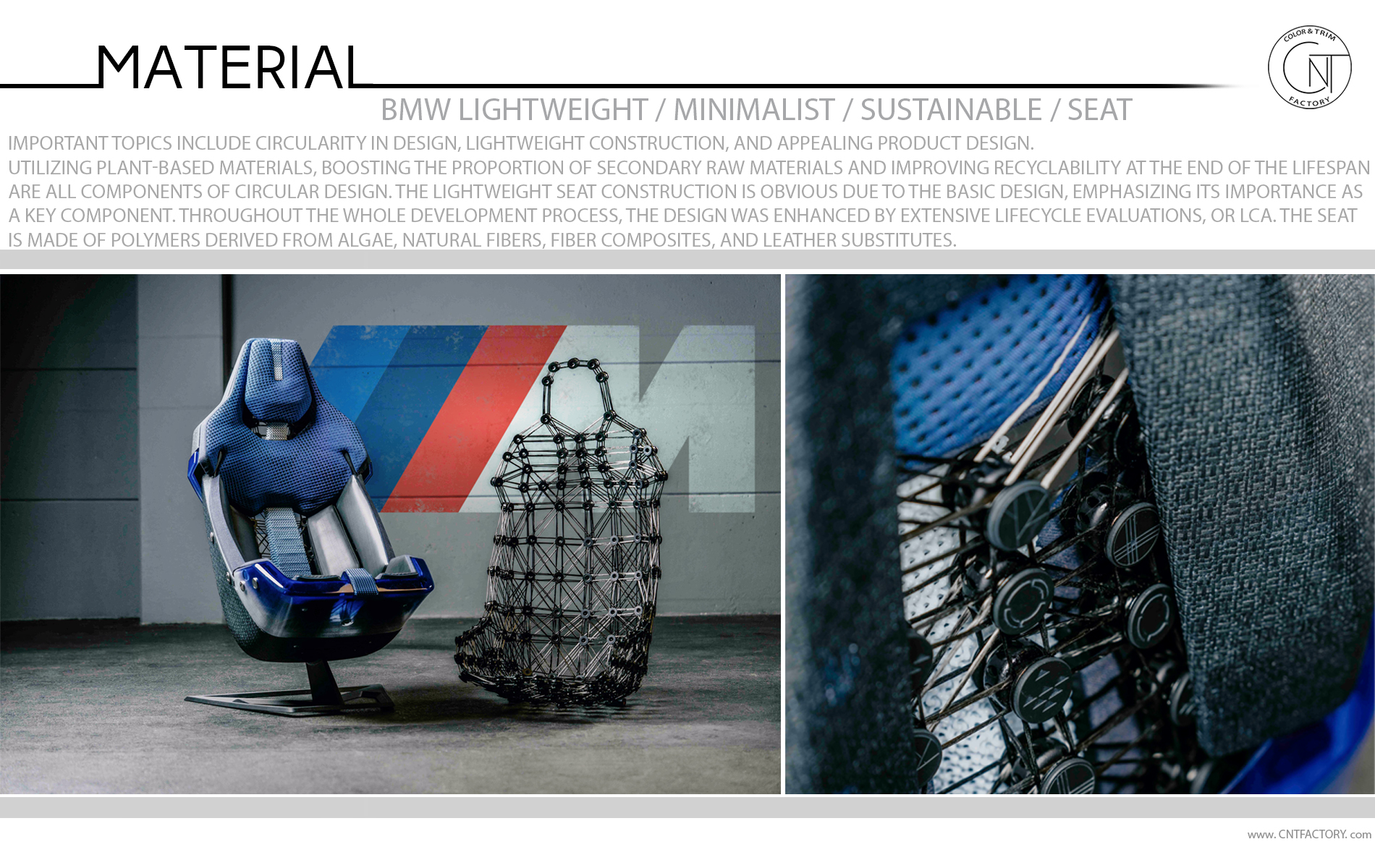

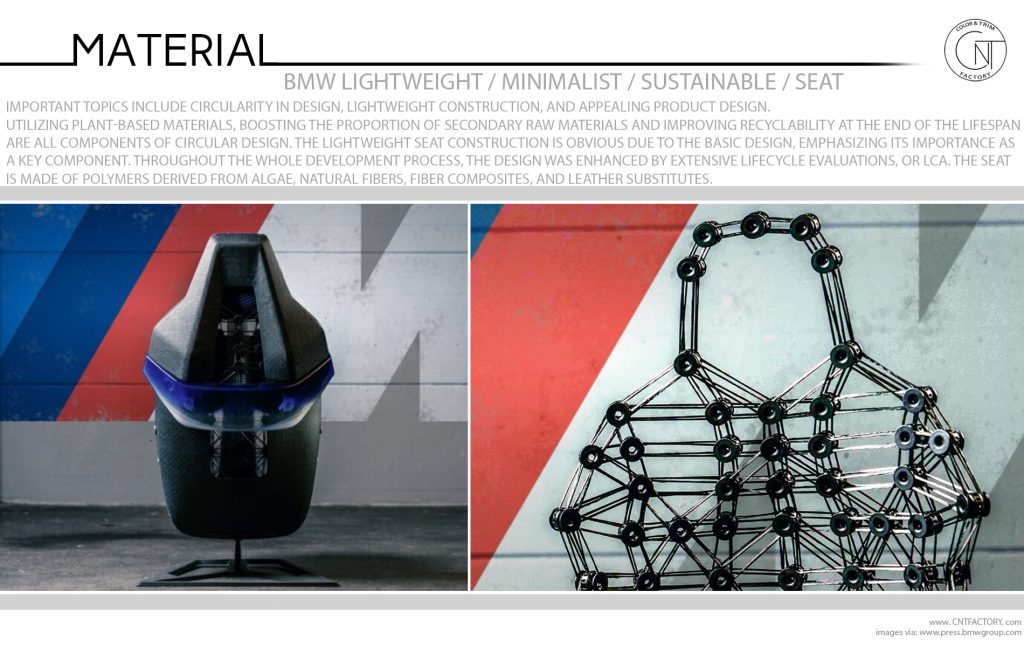

Important topics include circularity in design, lightweight construction, and appealing product design.

Utilizing plant-based materials, boosting the proportion of secondary raw materials and improving recyclability at the end of the lifespan are all components of circular design.

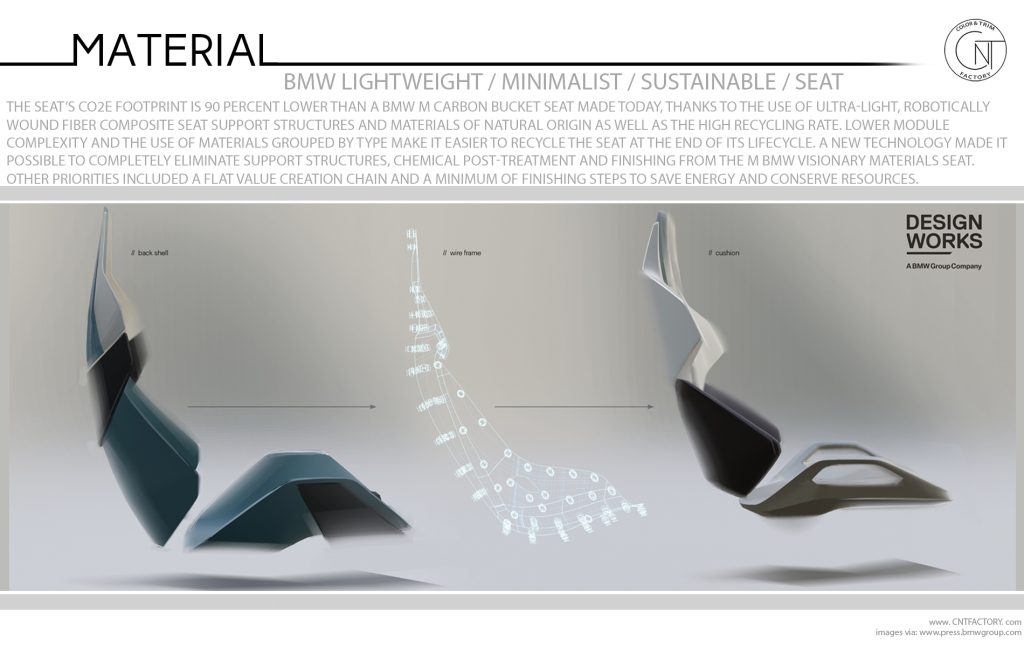

The lightweight seat construction is obvious due to the basic design, emphasizing its importance as a key component. Throughout the whole development process, the design was enhanced by extensive lifecycle evaluations, or LCA.The project’s central idea was to go forward while operating within the constraints of the present. Natural materials are the perfect complement, according to the examination of material classes that are currently available and have a high SQR (secondary raw material quota). For instance, the seat is made of polymers derived from algae, natural fibers, fiber composites, and leather substitutes.

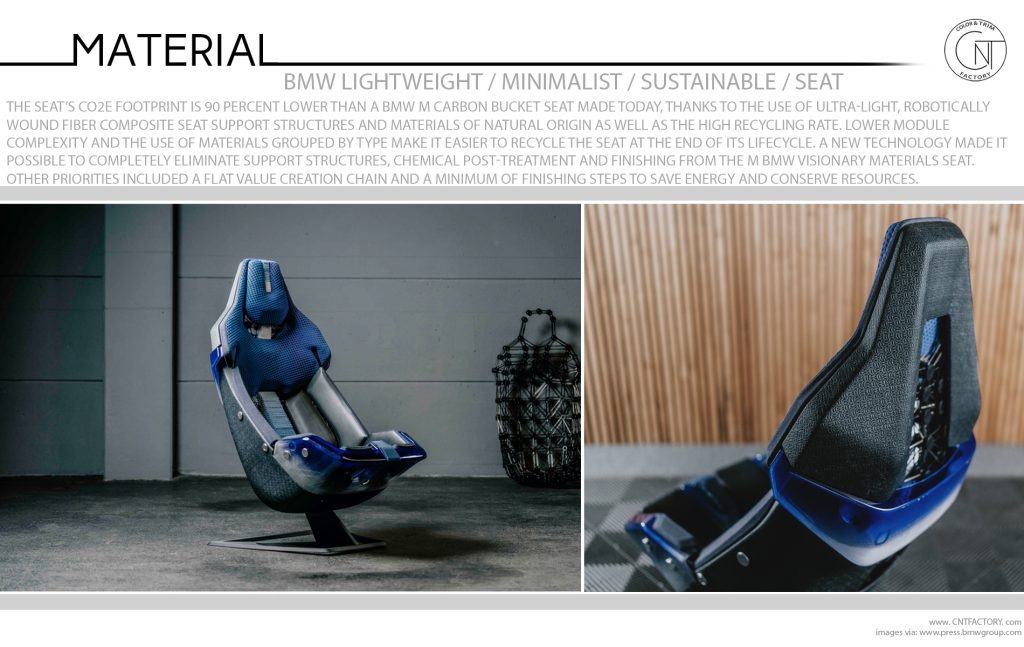

The seat’s CO2e footprint is 90 percent lower than a BMW M carbon bucket seat made today, thanks to the use of ultra-light, robotically-wound fiber composite seat support structures and materials of natural origin as well as the high recycling rate. In addition, lower module complexity and the use of materials grouped by type make it easier to recycle the seat at the end of its lifecycle. The additive manufacturing processes used are also groundbreaking: A new technology made it possible to completely eliminate support structures, chemical post-treatment and finishing from the M BMW Visionary Materials Seat. Other priorities included a flat value creation chain and a minimum of finishing steps to save energy and conserve resources.