Sorry, this content is for members only.

Join To View ThisRelated Post: Regenerated Nylon ECONYL® / Recycled Plastic by Ecobirdy / Sulapac® Biodegradable Material

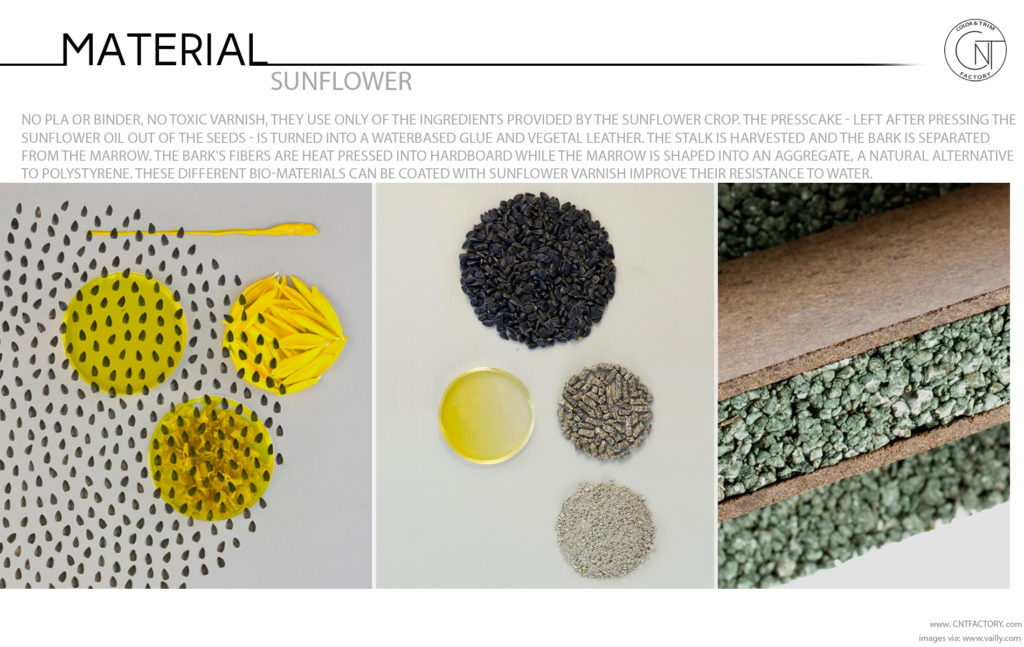

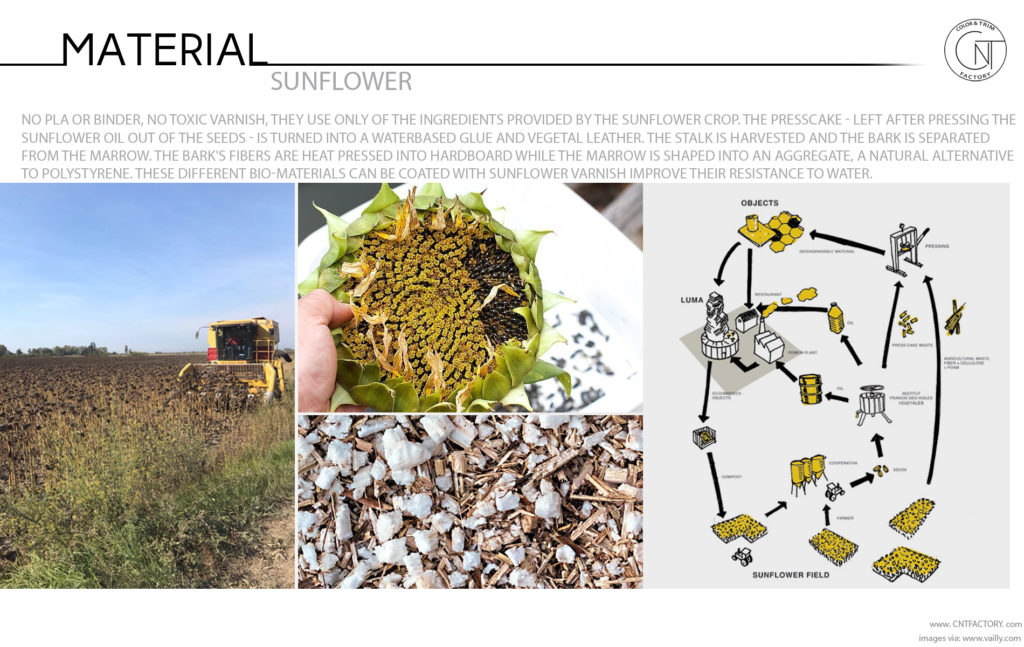

Sunflowers are commonly farmed to produce oil, seeds or bio-fuel. After pressing the oil out, a part can be used as animal feed – the press cake – but most of the crop remain unused. The stalk’s foamy structure, the strong fiber of the bark or the flower’s dark brown proteins are left behind. These agro-waste can be valuable resources to produce novel bio materials.

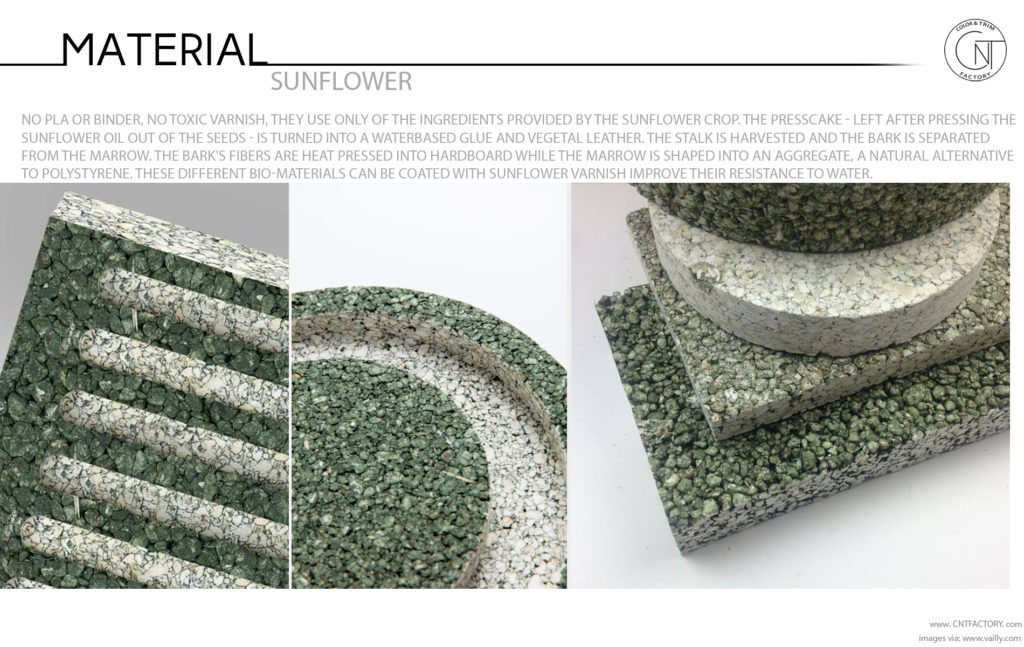

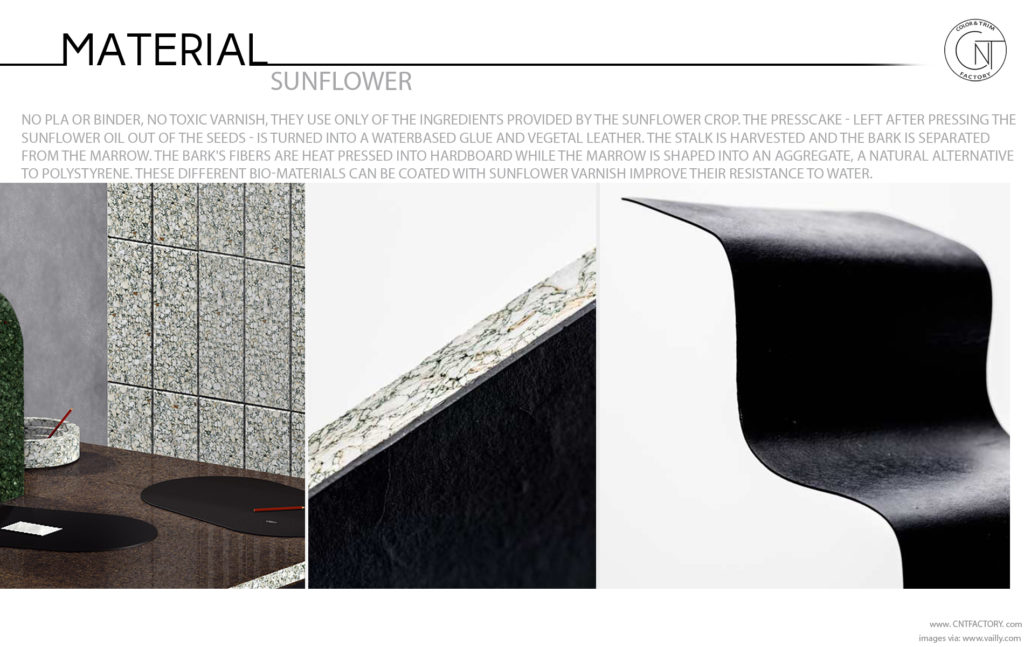

No synthetic binder, no toxic varnish, all the necessary ingredients are extracted from the sunflower crop. The press cake – the remain of Sunflower seed after the oil has been extracted – is turned into a water based glue and heat pressed into a thin and flexible film resembling leather.

Traditionally, only the flower head is harvested in late summer. However, the stalk of the plant can also be used. Harvested a month after the flower head, the bark – fibers – can be separated from the marrow – foamy structure. The bark’s fibers are heat pressed into hardboard while the marrow is shaped into an aggregate, a natural alternative to polystyrene. These different bio-materials can be coated with a Sunflower varnish to enhance their resistance to water. The glue extracted from the seeds is the perfect adhesive to assemble these different materials. The Sunflower crop offers a unique range of bio-based and bio-degradable material. Entering the realm of bio-plastics, a vast number of applications of what was previously considered waste becomes possible: from a tiny bolt to a large insulation panel, from a bio-board to an smartphone case.

concept & design by studio Thomas Vailly for Atelier Luma

In collaboration the INRA/INP-ENSIACET, A. Rouilly & P. Evon