Sorry, this content is for members only.

Join To View ThisRelated Post: Parley x Corona / Ecobirdy / Regenerated Nylon Econyl® From Aquafil

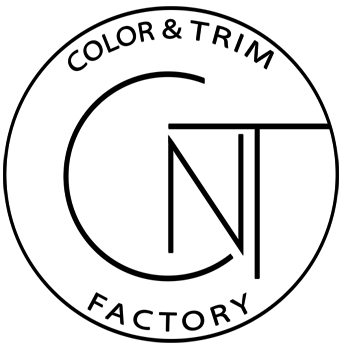

Prada Re-Nylon reinvents the idea of timeless, as something that can truly last forever.

Re-Nylon is a bold move towards total sustainability – towards an ultimate goal of converting all Prada virgin nylon into regenerated nylon ECONYL® by the end of 2021. It reflects the focus of the Prada Group on promoting a corporate culture that aspires to increasingly sustainable balances, incorporating into its daily work the idea of a return of value to society.

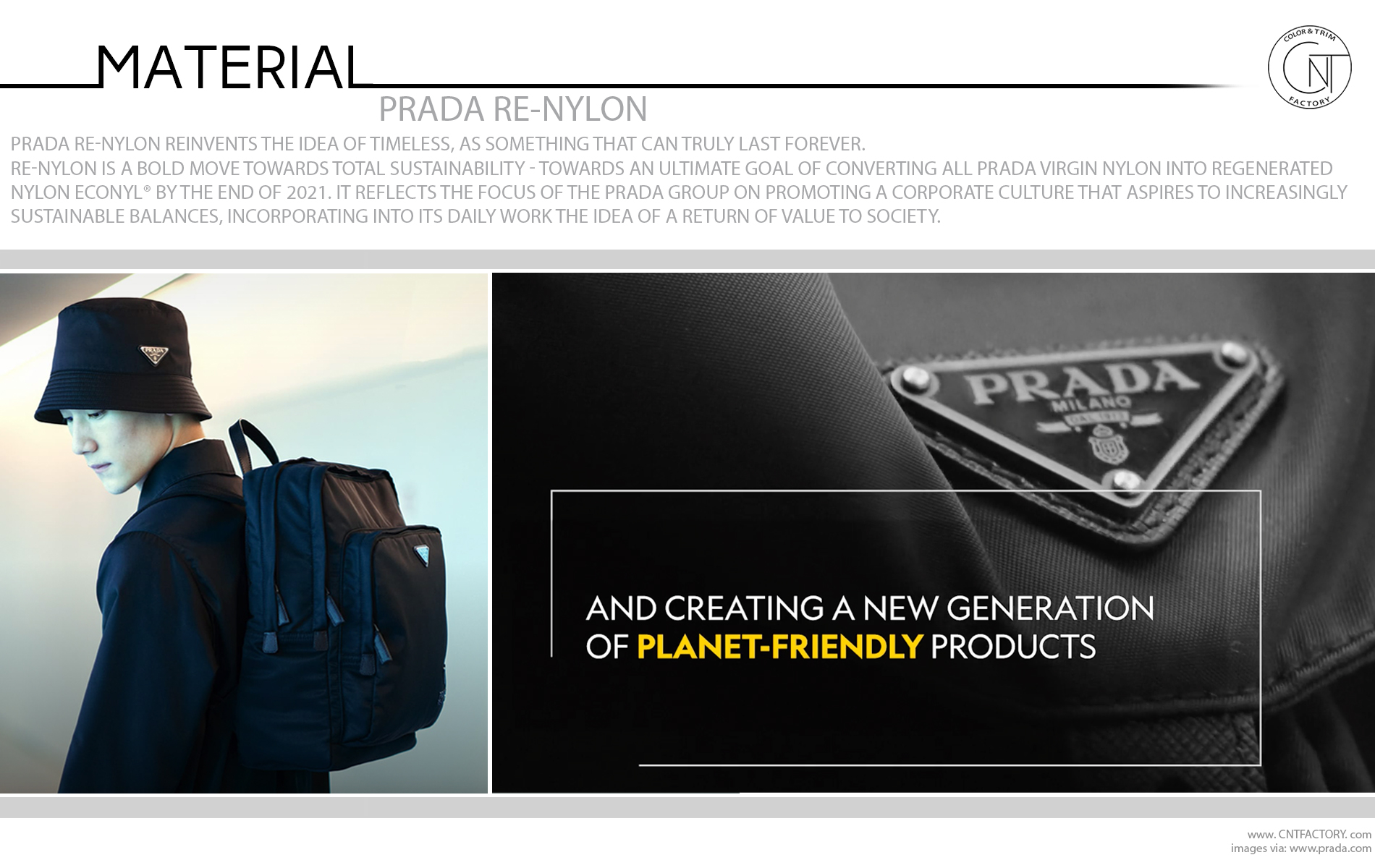

Phoenix Arizona, first US carpet recycling facility which can recycle up to 16,000 metric tons each year. Less than 3% of the 1.6 million tons of carpet discarded in the US each year is recycled: in this video, actress and Prada reporter Bonnie Wright and National Geographic explorer and creative conservationist Asher Jay show us one of the sources of ECONYL® nylon and unpack a new cyclical supply-chain upending traditional notions of production for a new generation.

Re-Nylon is a bold move towards total sustainability – towards an ultimate goal of converting all Prada virgin nylon into regenerated nylon ECONYL® by the end of 2021. The product of a partnership between Prada and the textile yarn producer Aquafil, ECONYL® nylon is obtained through the recycling and purification process of plastic waste collected from oceans, fishing nets, and textile fibre waste.

ECONYL® yarn, through a process of depolymerization and re-polymerisation, can be recycled indefinitely, with no loss of quality.

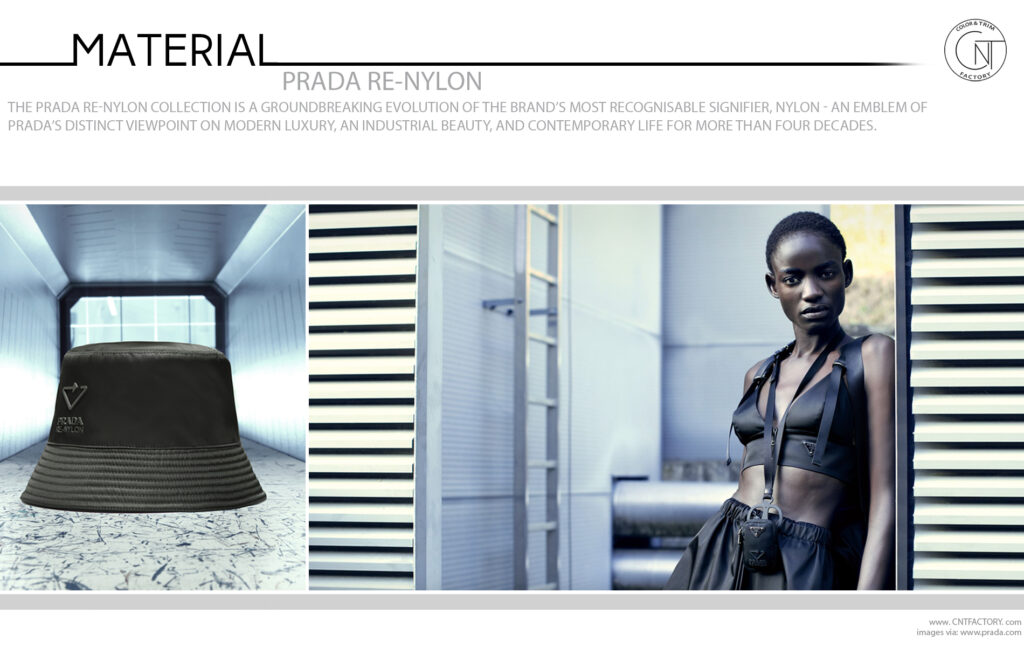

The Prada Re-Nylon collection is a groundbreaking evolution of the brand’s most recognizable signifier, nylon – an emblem of Prada’s distinct viewpoint on modern luxury, an industrial beauty, and contemporary life for more than four decades.

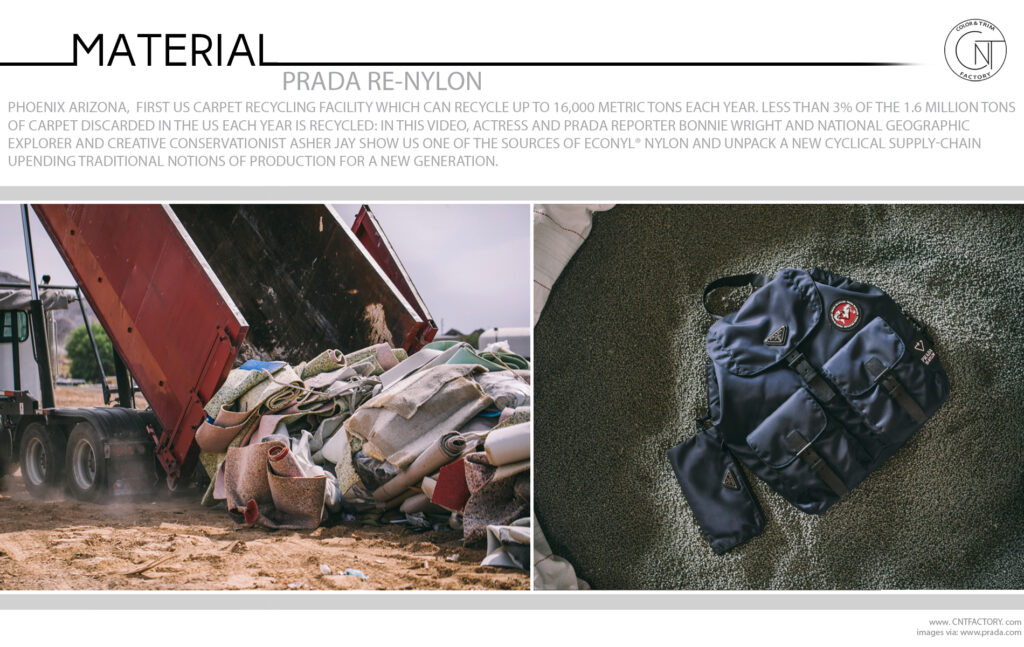

Slovenia, a country which has latterly become a hub of a new regenerative and sustainable industry, with 40,000 tons of material recycled annually. It is also home of Aquafil’s production plant for ECONYL®, established in the city of Ljubljana. Where we are allowed to see some of the intricate chemical recycling process of depolymerisation, used to transforming tons of collected waste into pristine, pioneering new ECONYL® yarn.

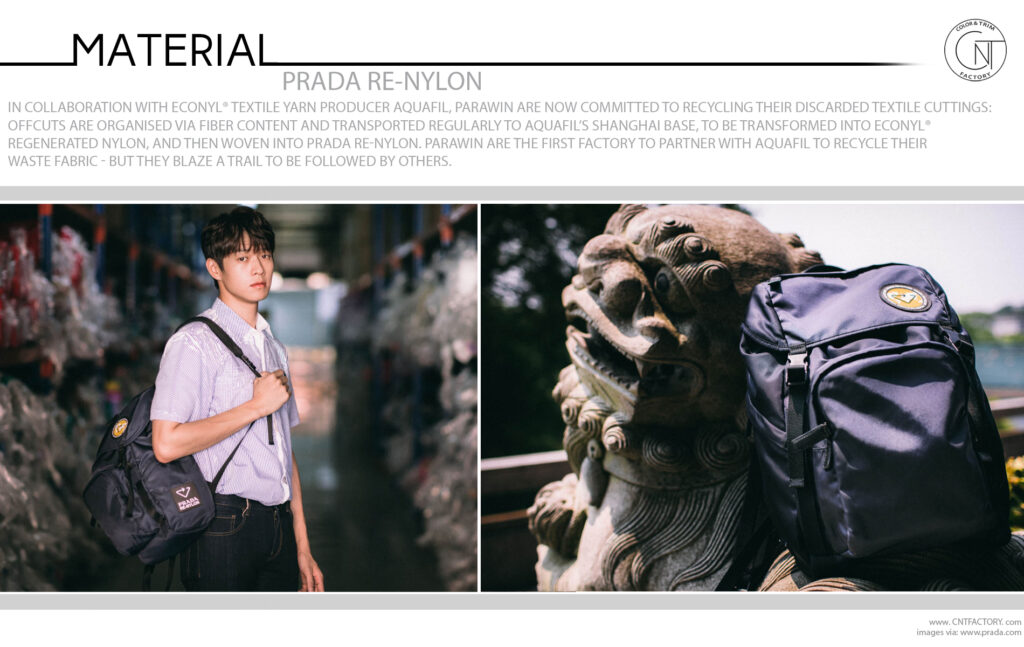

In collaboration with ECONYL® textile yarn producer Aquafil, Parawin are now committed to recycling their discarded textile cuttings: offcuts are organised via fiber content and transported regularly to Aquafil’s Shanghai base, to be transformed into ECONYL® regenerated nylon, and then woven into Prada Re-Nylon. Parawin are the first factory to partner with Aquafil to recycle their waste fabric – but they blaze a trail to be followed by others.