Related Post: Wood Veneer Craftsmanship / Carved 3D Wood Quilting / Kumiko Woodwork Technique

Aectual’s Wood Series debuts with a range of customizable window coverings and partition screens, launching an expanding line of 3D Printed Wood products. Because the novel material can be reprinted after use, traps CO2, and is completely biodegradable, it perfectly fits with Aectuals Circular purpose.

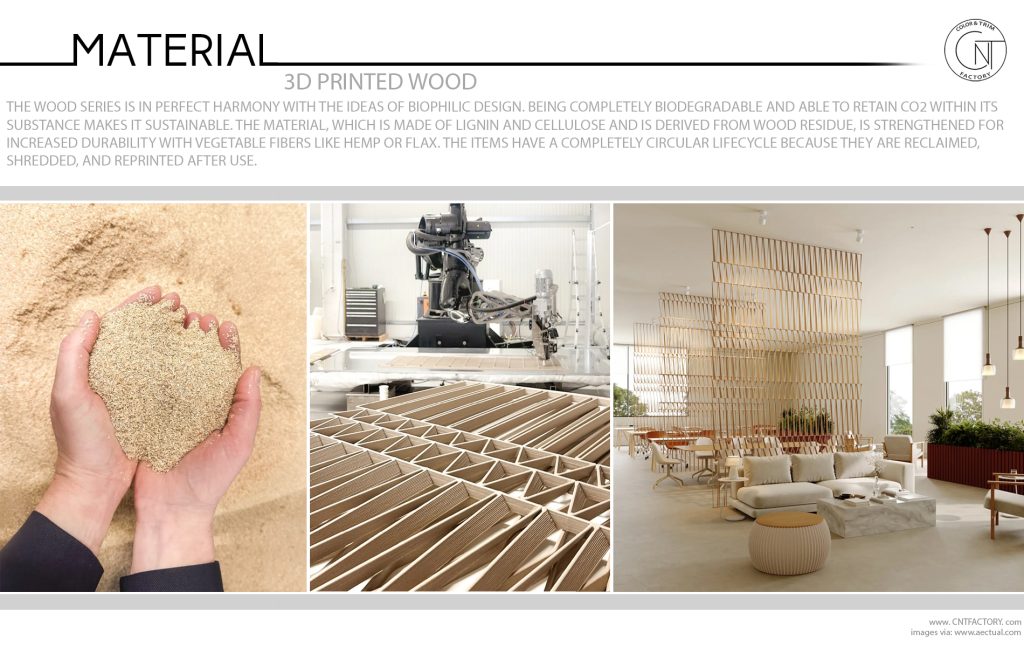

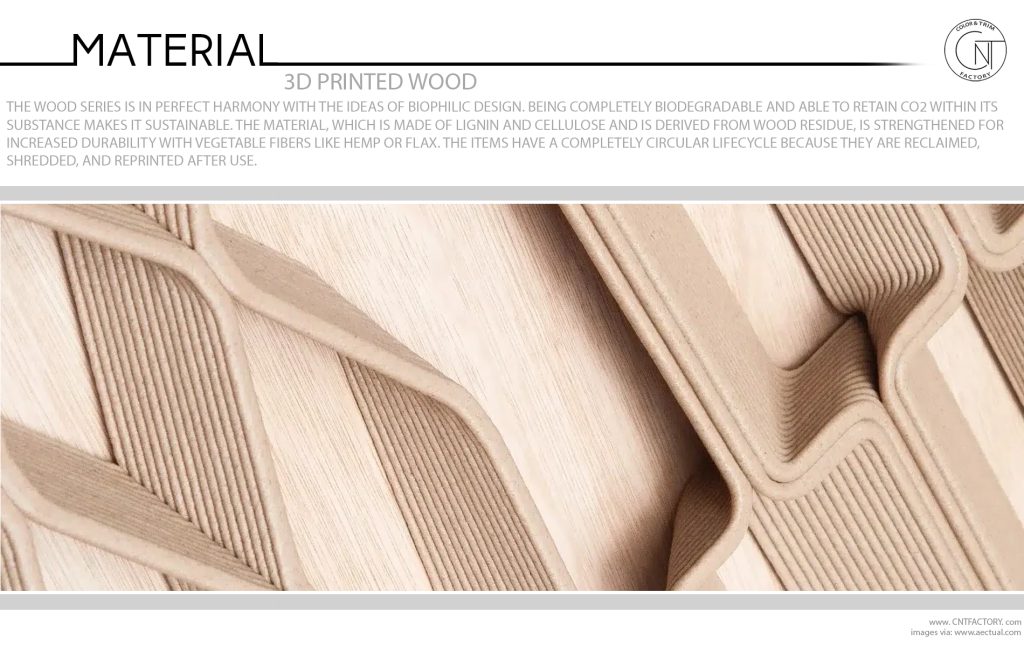

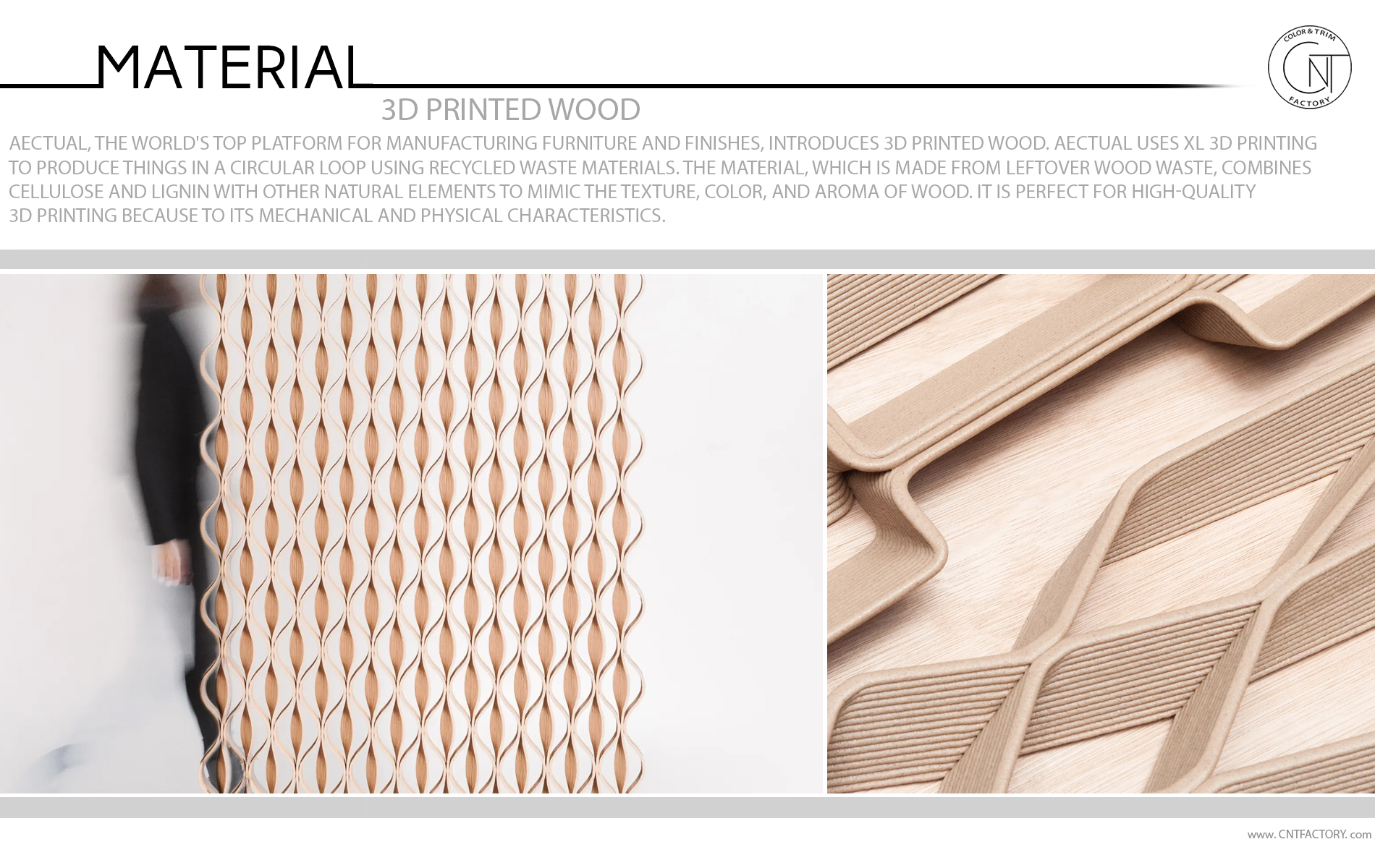

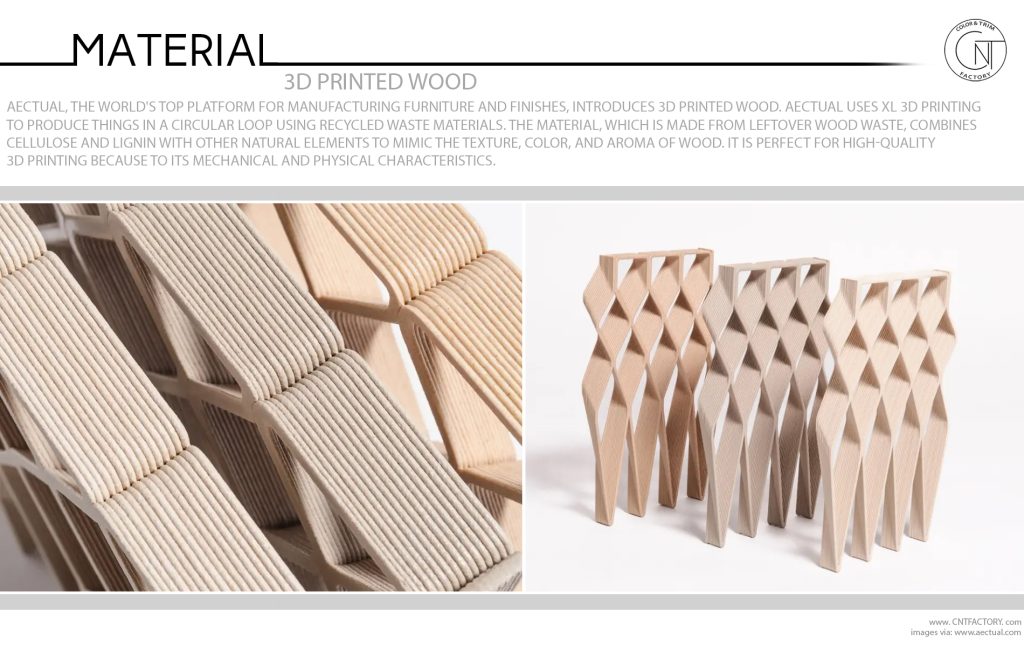

Aectual, the world’s top platform for manufacturing furniture and finishes, introduces 3D Printed Wood. Aectual uses XL 3D printing to produce things in a circular loop using recycled waste materials. The material, which is made from leftover wood waste, combines cellulose and lignin with other natural elements to mimic the texture, color, and aroma of wood. It is perfect for high-quality 3D printing because to its mechanical and physical characteristics.

The Wood Series is in perfect harmony with the ideas of biophilic design. Being completely biodegradable and able to retain CO2 within its substance makes it sustainable. The material, which is made of lignin and cellulose and is derived from wood residue, is strengthened for increased durability with vegetable fibers like hemp or flax. The items have a completely circular lifecycle because they are reclaimed, shredded, and reprinted after use.